Welding Terms and Definitions Dictionary

- Some information courtesy of American Welding Society, Lincoln Electric and Miller Welds -

|

AC Aluminum Pulse

- With the help of the Lincoln Electric Power Wave® Advanced Module, GMAW aluminum welding results can be improved over traditional DC positive aluminum MIG welding. By switching the polarity of the arc, heat input is reduced and deposition rates are enhanced.

|

AC-STT®

- Based off Lincoln Electric’s patented STT® process, AC-STT® combines the proven spatter reducing technology of the STT® waveform with the balanced heat-input characteristics of AC GMAW, producing an advanced short circuit process optimized specifically for thin-gauge materials.

|

Accu-Pulse®

- MIG process that delivers precise control of the arc even over tack welds and in tight corners. Provides optimum and precise molten puddle controL. A Miller Tehnology Exclusive.

|

Accu-Rated™ Power

- The standard for measuring engine-driven generator power. Guarantees delivery of all power promised. A Miller Technology Exclusive.

|

Across the arc wire feeders

- Also referred to as voltage-sensing wire feeders. The wire feeder is powered by the welding cable instead of a control cable. This configuration provides the benefit of fewer cables running back to the power source. Voltage control at the point of use is not possible without the addition of a control cable however, technologies such as ArcReach and CrossLinc now provided remote control capability via the welding cable.

|

Active Arc Stabilizer™

- A Miller Technology Exclusive - Active Arc Stabilizer enhances arc starts and provides a softer arc throughout all ranges, with less puddle turbulence and less spatter.

|

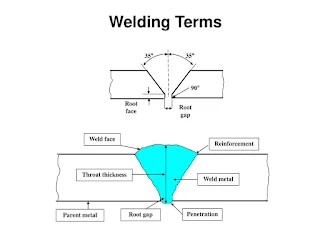

Actual throat

- The shortest distance from the root of a fillet weld to its face.

|

Adaptive Hot Start™

- Automatically increases the output amperage at the start of a stick weld, should the start require it. Helps eliminate sticking of the electrode at arc start. A Miller Technology Exclusive. Available on these machines: 12VX Extreme Duty, EXtreme 360 MAP , Miller Syncrowave 250 DX , Miller Syncrowave 350 LX , Miller XMT 350 MPa

|

Advanced Active Field Control Technology™

- A simple and reliable patented way of accurately controlling an engine drive's generator weld output. A Miller Technology Exclusive.

|

All-weld-metal test specimen

- A test specimen with the reduced section composed wholly of weld metal

|

Alloy

- A mixture of metallic elements combined to provide specific properties such as greater resistance to corrosion or improved strength. For example, brass is an alloy of copper and zinc; steel is an alloy of iron and carbon.

|

Alternating Current (AC)

- An electric current which periodically reverses direction. It is the form in which electric power is delivered to businesses and residences.

|

Aluminum Pulse Hot Start™

- This Miller Technology Exclusive automatically provides more arc power to the Millermatic® 350P to eliminate a "cold start" that is inherent with aluminum starts.

|

Amperage

- The measurement of the amount of electricity flowing past a given point in a conductor per second. Current is another name for amperage.

|

Arc

- The physical gap between the end of the electrode and the base metal. The physical gap causes heat due to resistance of current flow and arc rays.

|

Arc blow

- The deflection of an electric arc from its normal path because of magnetic forces.

|

Arc force

- Arc force prevents the electrode from sticking during welding. Arc force is a temporary increase of the output current during welding when the arc is too short. This feature supports production with consistently excellent arc performance. It also enhances simple position welding making the job easier. In order to produce an outstanding weld performance on a variety of electrodes (rutile, basic or cellulose), the arc force can be finely adjusted with a simple knob. To have a smooth arc with less spatter, set the knob to minimum (rutile, basic). For a more crisp arc, with more penetration, set it to maximum.

|

Arc seam weld

- A seam weld made by an arc welding process.

|

Arc spot weld

- A spot weld made by an arc welding process.

|

Arc time

- The time during which an arc is maintained in making an arc weld.

|

Arc voltage

- The voltage across the welding arc.

|

Arc Welding

- Welding processes which use heat from the resistance of current flow and arc rays to produce coalescence of metals. Can use either direct (DC) or alternating (AC) current, consumable or non-consumable electrodes, with or without the application of pressure.

|

Arc welding electrode

- A component of the welding circuit through which current is conducted between the electrode holder and the arc.

|

Arc welding gun

- In semi-automatic, machine and automatic welding, a manipulating device to transfer current and guide the electrode into the arc. It may include provisions for shielding and arc initiation.

|

Arc-Drive

- Automatically enhances Stick welding, especially on pipe, by focusing the arc and preventing the electrode from going out. A Miller Technology Exclusive.

|

ArcReach

- Technology developed by Miller Electric that provides the ability for a welding operator to make parameter adjustments at the wire feeder without the need for control cords or specialized wireless remotes. Voltage changes are communicated from the wire feeder to the power source using existing welding cables.

|

As-welded

- The condition of weld metal, welded joints, and weldments after welding but prior to any subsequent thermal, mechanical, or chemical treatments.

|

Auto Remote Sense™

- Automatically switches machine from panel to remote control with remote connected. Available on Dimension™ NT 450, XMT® 350, Trailblazer® Series, and PRO 300. Eliminates confusion and need for panel/remote. A Miller Technology Exclusive

|

Auto-Crater™

- This Miller Technology Exclusive allows a TIG arc on the Trailblazer® Series to crater-out, allowing time for the addition of filler, without the loss of shielding gas. Eliminates the need for a remote control at arc end.

|

Auto-Line™

- This Miller Technology Exclusive allows for any primary input voltage within a range, single- or three-phase, 50 or 60 Hz. Also adjusts for voltage spikes within the entire range.

|

Auto-Link®

- Internal inverter power source circuit that automatically links the power source to the primary voltage being applied (230 V or 460 V), without the need for manually linking primary voltage terminals. A Miller Technology Exclusive.

|

Auto-Refire™

- This Miller Technology Exclusive automatically controls the pilot arc when cutting expanded metal or multiple pieces of metal, without manual re-triggering.

|

Auto-Stop™

- This Miller Technology Exclusive allows a TIG arc to be stopped without the loss of shielding gas on the Trailblazer® Series.

|

Autogenous weld

- A fusion weld made without the addition of filler metal.

|

Automatic Start at Idle

- This Miller Technology Exclusive idles engine immediately when started, extending engine life and reducing fuel consumption and noise.

|

Automatic Welding

- Uses equipment that welds without the constant adjusting of controls by the welder or operator. Equipment controls joint alignment by using an automatic sensing device.

|

Automatic welding

- Welding with equipment which performs the welding operation without adjustment of the controls by a welding operator. The equipment may of may not perform the loading and unloading of the work. See machine welding.

|

Axcess™ File Management

- Software that turns a standard Palm handheld into a data card and a remote pendant for all Axcess systems. Allows emailing, storage and transfer of welding programs. A Miller Technology Exclusive.

|

Axis of a weld

- A line through the length of a weld, perpendicular to and at the geometric center of its cross section.

|

Back gouging

- The removal of weld metal and base metal from the other side of a partially welded joint to assure complete penetration upon subsequent welding from that side.

|

Backhand welding

- A welding technique in which the welding torch or gun is directed opposite to the progress of welding. Sometimes referred to as the “pull gun technique” in GMAW and FCAW.

|

Backing

- A material (base metal, weld metal, carbon, or granular material) placed at the root of a weld joint for the purpose of supporting molten weld metal.

|

Backing pass

- A pass made to deposit a baking weld.

|

Backing ring

- Backing in the form of a ring, generally used in the welding of piping.

|

Backing strip

- Backing in the form of a strip.

|

Backstep sequence

- A longitudinal sequence in which the weld bead increments are deposited in the direction opposite to the progress of welding the joint. See block sequence, cascade sequence,continuous sequence, joint building sequence, and longitudinal sequence.

|

Bare electrode

- A filler metal electrode consisting of a single metal or alloy that has been produced into a wire, strip, or bar form and that has had no coating or covering applied to it other than that which was incidental to its manufacture or preservation.

|

Bare metal arc welding (BMAW)

- An arc welding process which produces coalescence of metals by heating them with an electric arc between a bare or lightly coated metal electrode and the work. Neither shielding nor pressure is used and filler metal is obtained from the electrode. (This process is now obsolete in industrial applications).

|

Base metal (material)

- The metal (material) to be welded, brazed, soldered, or cut.

|

Base metal test specimen

- A test specimen composed wholly of base-metal.

|

Bevel

- An angular type of edge preparation.

|

Bevel angle

- The angle formed between the prepared edge of a member and a plane perpendicular to the surface of the member.

|

Blind joint

- A joint, no portion of which is visible.

|

Block sequence

- A combined longitudinal and buildup sequence for a continuous multiple pass weld in which separated lengths are completely or partially built up in cross section before intervening lengths are deposited.

|

Boxing

- The continuation of a fillet weld around a corner of a member as an extension of the principal weld.

|

Burn-thru

- A term erroneously used to denote excessive melt-thru or a hole.

|

Burn-thru weld

- A term erroneously used to denote a seam weld or spot weld.

|

Butt joint

- A joint between two members aligned approximately in the same plane.

|

Butt weld

- An erroneous term for a weld in a butt joint.

|

Buttering

- A form of surfacing in which one or more layers of weld metal are deposited on the groove face of one member (for example, a high alloy weld deposit on steel base metal which is to be welded to a dissimilar base metal). The buttering provides a suitable transition weld deposit for subsequent completion of the butt weld.

|

Button

- That part of a weld, including all or part of the nugget, which tears out in the destructive testing of spot, seam, or projection welded specimens.

|

Carbon arc cutting (CAC)

- An arc cutting process in which metals are severed by melting them with the heat of an arc between a carbon electrode and the base metal.

|

Carbon arc welding (CAW)

- An arc welding process which produces coalescence of metals by heating them with an arc between a carbon electrode and the work. No shielding is used. Pressure and filler metal may or may not be used.

|

Carbon electrode

- A non-filler material electrode used in arc welding or cutting, consisting of a carbon or graphite rod, which may be coated with copper or other coatings.

|

Cascade sequence

- A combined longitudinal and buildup sequence during which weld beads are deposited in overlapping layers.

|

Center of gravity (weld positioning)

- The point at which the weldment balances on all axes equally. As the distance increases from the device, more torque is applied to the positioner. The center of gravity changes as the welder adds material and parts to the positioner.

|

Chain intermittent fillet welding

- Two lines of intermittent fillet welds on a joint in which the fillet weld increments on one side are approximately opposite to those on the other side of the joint.

|

Clad metal

- A composite metal containing two or three layers that have been welded together. The welding may have been accomplished by roll welding, arc welding, casting, heavy chemical deposition or heavy electroplating.

|

Cladding

- A relatively thick layer (> 1 mm (0.04 in.)) of material applied by surfacing of the purpose of improved corrosion resistance or other properties. Cladding Systems

|

Coalescence

- The growing together or growth into one body of the materials being welded.

|

Coating

- A relatively thin layer (> 1 mm (0.04 in.)) of material applied by surfacing for the purpose of corrosion prevention, resistance to high temperature scaling, wear resistance, lubrication, or other purposes.

|

Coil with support

- A filler metal package type consisting of a continuous length of electrode in coil form wound on an internal support which is a simple cylindrical section without flanges.

|

Coil without support

- A filler metal package type consisting of a continuous length of electrode in coil form without an internal support. It is appropriately bound to maintain its shape.

|

Complete fusion

- Fusion which has occurred over the entire base material surfaces intended for welding, and between all layers and passes.

|

Complete joint penetration

- Joint penetration in which the weld metal completely fills the groove and is fused to the base metal throughout its total thickness.

|

Composite electrode

- Any of a number of multicomponent filler metal electrodes in various physical forms such as stranded wires, tubes, and covered wire.

|

Composite joint

- A joint produced by welding used in conjunction with a non-welding process.

|

Concave fillet weld

- A fillet weld having a concave face.

|

Concave root surface

- A root surface which is concave.

|

Concavity

- The maximum distance from the face of a concave fillet weld perpendicular to a line joining the toes.

|

Concurrent heating

- The application of supplemental heat to a structure during a welding or cutting operation.

|

Constant Current (CC) Welding Machine

- These welding machines have limited maximum short circuit current. They have a negative volt-amp curve and are often referred to as "droopers."

|

Constant speed wire feeders

- A constant speed wire feeder is used only with a constant voltage (CV) power source. This arrangement requires an extra control cord between the wire feeder and the power source but that allows operators to control both voltage and wire feed speed (amperage) at the feeder, a big benefit when working remotely. Further, voltage and amperage values remain constant unless manually adjusted, and both can be adjusted independently of each other. When welding procedures specify wire feed speed and voltage (instead of amps and volts), a constant speed feeder may be your best choice. When you set the controls for a wire feed speed of 250 inches per minute, that's what the system delivers. Wire feed speed does not vary like it does with a voltage sensing system. Both VS and RC feeders have digital meters, typically an option, make setting e xact parameters easier. The meters display wire feed speed or volts (one at a time) or they can be set to display amps or wire feed speed (one at a time).

|

Constant Voltage (CV), Constant Potential (CP) Welding Machine

- This type of welding machine output maintains a relatively stable, consistent voltage regardless of the amperage output. It results in a relatively flat volt-amp curve.

|

Consumable guide electro slag welding

- A method of electroslag welding in which filler metal is supplied by an electrode and its guiding member.

|

Consumable insert

- Preplaced filler metal which is completely fused into the root of the joint and becomes part of the weld.

|

Contact tube

- A device which transfers current to a continuous electrode.

|

Continuous sequence

- A longitudinal sequence in which each pass is made continuously from one end of the joint to the other.

|

Continuous weld

- A weld extends continuously from one end of a joint to the other. Where the joint is essentially circular, it extends completely around the joint.

|

Convex fillet weld

- A fillet weld having a convex face.

|

Convex root surface.

- A root surface which is convex.

|

Convexity

- The maximum distance from the face of a convex fillet weld perpendicular to a line joining the toes.

|

Cool-On-Demand™

- Integrated cooler runs only when needed on Syncrowave® 250 DX and 350 LX. A Miller Technology Exclusive.

|

Corner joint

- A joint between two members located approximately at right angles to each other.

|

Corner-flange weld

- A flange weld with only one member flanged at the location of welding.

|

Cover lens (eye protection)

- A round cover plate.

|

Cover plate (eye protection)

- A removable pane or colorless glass, plastic-coated glass, or plastic that covers the filter plate and protects it from weld spatter, pitting, or scratching when used in a helmet, hood or goggle.

|

Covered electrode

- A composite filler metal electrode consisting of a core of a bare electrode or metal cored electrode to which a covering sufficient to provide a slag layer on the weld metal has been applied. The covering may contain materials providing such functions as shielding from the atmosphere, deoxidation, and arc stabilization and can serve as a source of metallic additions to the weld.

|

Crack

- A fracture-type discontinuity characterized by a sharp tip and high ratio to length and width to opening displacement.

|

Crater

- In arc welding, a depression at the termination of a weld bead or in the molten weld pool.

|

Crater crack

- A crack in the crater of a weld bead.

|

CrossLinc

- A technology developed by Lincoln Electric that provides the ability for the operator to adjust voltage at the wirefeeder without the need for an additional control cable or wireless remote. Voltage changes are communicated from the wire feeder to the power source using existing welding cables.

|

Current

- Another name for amperage. The amount of electricity flowing past a point in a conductor every second.

|

CV

- Conventional mode for MIG welding. This general purpose MIG welding mode uses constant voltage for short arc, globular and spray transfer.

|

Cylinder

- A portable container used for transportation and storage of a compressed gas.

|

Defect

- A discontinuity or discontinuities which by nature or accumulated effect (for example, total crack length) render a part or product unable to meet minimum applicable acceptance standards or specifications. This terms designates reject ability.

|

Defective weld

- A weld containing one or more defects.

|

Deposited metal

- Filler metal that has been added during a welding operation.

|

Deposition efficiency (arc welding)

- The ratio of the weight of deposited metal to the net weight of filler metal consumed, exclusive of stubs.

|

Depth of fusion

- The distance that fusion extends into the base metal or previous pass from the surface melted during welding.

|

Dig

- Also called Arc Control. Gives a power source variable additional amperage during low voltage (short arc length) conditions while welding. Helps avoid “sticking” stick electrodes when a short arc length is used.

|

Dilution

- The change in chemical composition of a welding filler material caused by the admixture of the base material or previously deposited weld material in the deposited weld bead. It is normally measured by the percentage or base material or previously deposited weld material in the weld bead.

|

Direct Current (DC)

- Flows in one direction and does not reverse its direction of flow as does alternating current.

|

Direct current electrode negative

- The arrangement of direct current arc welding leads in which the work is the positive pole and the electrode is the negative pole of the welding arc.

|

Direct current electrode positive

- The arrangement of direct current arc welding leads in which the work is the negative pole and the electrode is the positive pole of the welding arc.

|

Discontinuity

- An interruption of the typical structure of a weldment, such as a lack of homogeneity in the mechanical, metallurgical, or physical characteristics of the material or weldment. A discontinuity is not necessarily a defect.

|

Double-welded joint

- In arc and oxyfuel gas welding, any joint welded from both sides.

|

Drag angle

- The travel angle when the electrode is pointing backward. This angle can be used to define the position of welding guns, welding torches, high energy beams, welding rods, thermal cutting and thermal spraying guns.

|

Drop-thru

- An undesirable sagging or surface irregularity, usually encountered when brazing or welding near the solidus of the base metal caused by overheating with rapid diffusion or alloying between the filler metal and the base metal.

|

Drum

- A filler metal package type consisting of a continuous length of electrode wound or coiled within an enclosed cylindrical container.

|

Dual Fuel Generators

- Power generators which can run on 2 different fuels such as diesel or natural gas. Dual Fuel Generators can be more fuel efficient than other models and offer flexibility.

|

Dual Power Option™

- This Miller Technology Exclusive gives the option on the PipePro® 304 engine drive to use 230 volt single- or three-phase electric input power, eliminating engine wear, noise and emissions, as well as fuel costs.

|

Dustless Blasting

- Dustless wet media blasting is an excellentalternative to sandblasting. Sandblasting can create a lot of dust which requires specialized containment measures. Dustless blasting refers to blast cleaning methods like wet media blasting which don't produce any dust cloud. Any time a surface is cleaned with any blast cleaning method, there will always be some residual material (paint, rust, dirt etc) which is stripped away. The dust referred to in dustless blasting is that which comes from the blasting media itself ie. sand. The Clearblast 150 is a good example of a dustless blasting machine.

|

Duty cycle

- The percentage of time during an arbitrary test period, usually 10 min. during which a power supply can be operated at its rated output without overloading.

|

Eccentricity (weld positioning)

- The distance from the weldment center of gravity to its rotation axis in the case of an unbalanced load.

|

Edge flange weld

- A flange weld with two members flanged at the location of welding.

|

Edge joint

- A joint between the edges of two or more parallel or nearly parallel members.

|

Edge preparation

- The surface prepared on the edge of a member for welding.

|

Edge weld

- A weld in an edge point.

|

Effective length of weld

- The length of weld throughout which the correctly proportioned cross section exists. In a curved weld, it shall be measured along the axis of the weld.

|

Effective throat

- The minimum distance from the root of a weld to its face less any reinforcement.

|

Effective throat

- The minimum distance minus any reinforcement from the root of a weld to its face.

|

Electrode extension (GMAW, FCAW, SAW)

- The length of unmelted electrode extending beyond the end of the contact tube during welding.

|

Electrode holder

- A device used for mechanically holding the electrode while conducting current to it.

|

Electrode lead

- The electrical conductor between the source of arc welding current and the electrode holder.

|

Electroslag welding (ESW)

- A welding process producing coalescence of metals with molten slag which melts the filler metal and the surfaces of the work to be welded. The molten weld pool is shielded by this slag which moves along the full cross-section of the joint as welding progresses. The process is initiated by an arc which heats the slag. The arc is then extinguished and the conductive slag is maintained in a molten condition by its resistance to electric current passing between the electrode and the work.

|

Electroslag welding electrode

- A filler metal component of the welding circuit through which current is conducted between the electrode guiding member and the molten slag. Note: Bare electrodes and composite electrodes as defined under “arc welding electrode” are used for electroslag welding. A consumable guide may also be used as part of the electroslag welding electrode system.

|

Emissive electrode

- A filler metal electrode consisting of a core of a bare electrode or a composite electrode to which a very light coating has been applied to produce a stable arc.

|

Engine Save Start™

- Idles engine three - four seconds after starting on Trailblazer® 275 DC and 302. Extends engine life and reduces fuel consumption.A Miller Technology Exclusive.

|

Exhaust booth

- A mechanically ventilated, semi-enclosed area in which an air flow across the work area is used to remove fumes, gases, and material particles.

|

Face of weld

- The exposed surface of a weld on the side from which welding was done.

|

Face reinforcement

- Reinforcement of weld at the side of the joint from which welding was done.

|

Face shield (eye protection)

- A device positioned in front of the eyes and a portion of, or all of, the face, whose predominant function is protection of the eyes and face.

|

Fan-On-Demand™

- Internal power source cooling system that only works when needed, keeping internal components cleaner. A Miller Technology Exclusive.

|

FasTip™ Contact Tip

- Patented, single-turn for quick change — no tools needed. A Miller Technology Exclusive.

|

Faying surface

- That mating surface of a member which is in contact or in close proximity with another member to which it is to be joined.

|

Feed rate

- The rate at which material passes through a gun in a unit of times.

|

Ferrite number

- An arbitrary, standardized value designating the ferrite content of an austenitic stainless steel weld metal. It should be used in place of percent ferrite or volume percent ferrite on a direct one to one replacement basis.

|

Filled weld

- The position in which welding is performed on the upper side of an approximately horizontal plane and the face of the weld lies in an approximately vertical plane.

|

Filler metal

- The metal (material) to be added in making a welded, brazed, or soldered joint.

|

Fillet weld

- A weld of approximately triangular cross section joining two surfaces approximately at right angles to each other in a lap joint, T-joint or corner joint.

|

Fillet weld (size of weld)

- For equal leg fillet welds, the leg lengths of the largest isoceles right triangle which can be inscribed within the fillet weld cross section. For unequal leg fillet welds, the leg lengths of the largest right triangle which can be inscribed within the fillet weld cross section. Note: When one member makes an angle with the other member, greater that 105 degrees, the leg length (size) is of less significance than the effective throat which is the controlling factor for the strength of a weld.

|

Filter lens (eye protection)

- A round filter plate.

|

Filter plate (eye protection)

- An optical material which protects the eyes against excessive ultraviolet, infrared, and visible radiation.

|

Fines

- Any or all material finer than a particular mesh under consideration.

|

Fissure

- A small crack-like discontinuity with only slight separation (opening displacement) of the fracture surfaces. The prefixes macro or micro indicate relative size.

|

Fixed Automation

- Automated, electronically controlled welding system for simple, straight or circular welds.

|

Fixture

- A device designed to hold parts to be joined in proper relation to each other

|

Flange weld

- A weld made on the edges of two or more members to be joined, at least one of which is flanged.

|

Flange weld (size of weld)

- The weld metal thickness measured at the root of the weld.

|

Flat position

- The welding position used to weld from the upper side of the joint: the face of the weld is approximately horizontal.

|

Flaw

- A near synonym for discontinuity but with an undesirable connotation.

|

Flexible Automation

- Automated, robotically controlled welding system for complex shapes and applications where welding paths require torch-angle manipulation.

|

Flowability

- The ability of molten filler metal to flow or spread over a metal surface.

|

Flux

- Material used to prevent, dissolve, or facilitate removal of oxides and other undesirable surface substances.

|

Flux cored arc welding-electrogas

- A variation of the flux cored arc welding process in which molding shoes are used to confine the molten weld metal for vertical position welding. Additional shielding may or may not be obtained from an externally supplied gas or gas mixture.

|

Flux cored electrode

- A composition filler metal electrode consisting of a metal tube or other hollow configuration containing ingredients to provide such functions as shielding atmosphere, deoxidation, arc stabilization and slag formation. Alloying materials may be included in the core. External shielding may or may not be used.

|

Flux-Cored Arc Welding (FCAW)

- Arc welding process which uses a spooled, tubular filler metal electrode consumable enveloping flux. Shielding is obtained from the flux contained within the electrode core. Additional externally supplied shielding gas can also be used.

|

Forehand welding

- A welding technique in which the welding torch or gun is directed toward the progress of welding.

|

Full fillet weld

- A filler weld whose size is equal to the thickness of the thinner member joined.

|

Fusion

- The melting together of filler metal and base metal (substrate), or of base metal only, which results in coalescence.

|

Fusion face

- A surface of the base metal which will be melted during welding.

|

Fusion welding

- Any welding process or method which uses fusion to complete the weld.

|

Fusion zone

- The area of base metal melted as determined on the cross section of a weld.

|

Gas metal arc welding (GMAW)

- An arc welding process which produces coalescence of metals by heating them with an arc between a continuous filler metal (consumable) electrode and the work. Shielding is obtained entirely from an externally supplied gas or gas mixture. Some methods of this process are called MIG or CO2 welding (nonpreferred terms). See > MIG welding equipmentVideo > MIG (GMAW) welding

|

Gas metal arc welding short circuiting arc (GMAW-S)

- A variation of the gas metal arc welding process in which the consumable electrode is deposited during repeated short circuits.

|

Gas metal arc welding-electrogas (GMAW-EG)

- A variation of the gas metal arc welding process using molding shoes to confine the molten weld metal for vertical position welding.

|

Gas metal arc welding-pulsed arc (GMAW-P)

- A variation of the gas metal arc welding process in which the current is pulsed. See also pulsed power welding.

|

Gas shielding arc welding

- A general term used to describe gas metal arc welding, gas tungsten arc welding, and flux cored arc welding when gas shielding is employed.

|

Gas tungsten arc welding (GTAW)

- An arc welding process which produces coalescence of metals by heating them with an arc between a tungsten (non-consumable) electrode and the work. Shielding is obtained from a gas or gas mixture. Pressure may or may not be used and filler metal may or may not be used. (This process has sometimes been called TIG welding, a nonpreferred term.)

|

Gas tungsten arc welding-pulsed arc (GTAW-P)

- A variation of the gas tungsten arc welding process in which the current is pulsed.

|

Globular transfer (arc welding)

- A type of metal transfer in which molten filler metal is transferred across the arc in large droplets.

|

Goat

- Nickname for Lincoln Electric's LT7 submerged arc tractor

|

Gouging

- The forming of a bevel or groove by material removal. Learn about the Air Carbon Arc Gouging Process

|

Groove

- An opening or channel in the surface of a part or between two components which provides space to contain a weld.

|

Groove angle

- The total included angle of the groove between parts to be joined by a groove weld.

|

Groove face

- That surface of a member included in the groove.

|

Groove radius

- The radius used to form the shape of a J- or U-groove weld joint.

|

Groove type

- The geometric configuration of a groove.

|

Groove weld

- A weld made in the groove between two members to be joined. The standard types of groove welds are double-bevel-groove weld, double-flare-bevel-groove weld, double-flare-V-groove weld, double-J-groove weld, double-U-groove weld, double-V-groove weld single-bevel-groove weld, single-flare-bevel-groove weld, single-flare-V-groove weld single-J-groove weld, single-U-groove weld, single-V-groove weld, square-groove weld

|

Groove weld (size of weld)

- The joint penetration (depth of bevel plus the root penetration when specified). The size of a groove weld and its effective throat are one and the same.

|

Ground Connection

- A safety connection from a welding machine frame to the earth. See Workpiece Connection for the difference between work connection and ground connection.

|

Ground Lead

- When referring to the connection from the welding machine to the work, see preferred term Workpiece Lead.

|

Gun-On-Demand™

- This Miller Technology Exclusive allows you to use either a standard gun or a Spoolmatic® gun on Millermatic® 210, 251 and 350 without flipping a switch. The machine senses which gun you are using when you pull the trigger.

|

Hand shield

- A protective device, used in arc welding, for shielding the eyes, face and neck. A hand shield is equipped with a suitable filter plate and is designed to be held by the hand.

|

Hard facing

- A particular form of surfacing in which a coating or cladding is applied to a substrate for the main purpose of reducing wear or loss of material by abrasion, impact, erosion, galling, and cavitation. Article: Strengthening Metal Parts with Hardfacing

|

Heat-affected zone (HAZ)

- That portion of the base metal which has not been melted, but whose mechanical properties or microstructure have been already altered by the heat of welding, brazing, soldering, or cutting.

|

Helmet (eye protection)

- A protection device, used in arc welding, for shielding the eyes, face, and neck. A helmet is equipped with a suitable filter plate and is designed to be worn on the head.

|

Hertz

- Hertz is often referred to as "cycles per second." In the United States, the frequency or directional change of alternating current is usually 60 hertz.

|

High Frequency

- Covers the entire frequency spectrum above 50,000 Hz. Used in TIG welding for arc ignition and stabilization.

|

Horizontal fixed position (pipe welding)

- In pipe welding the position of a pipe joint in which the axis of the pipe is approximately horizontal and the pipe is not rotated during welding.

|

Horizontal rolled position (pipe welding)

- The position of a pipe joint in which the axis of the pipe is approximately horizontal, and welding is performed in the flat position by rotating the pipe.

|

Hot Start

- Hot Start provides a temporary increase of the output current during the start of a weld, which helps ignite the arc quickly and reliably. Hot Start provides excellent arc ignition without the electrode sticking and avoids any metallurgical default in the weld.

|

Hot Start™

- Used on some stick (SMAW) machines to make it easier to start difficult-to-start electrodes. Used for arc starting only. A Miller Technology Exclusive.

|

Inadequate joint penetration

- Joint penetration which is less than that specified.

|

Incomplete fusion

- Fusion which is less than complete.

|

Indentation

- In a spot, seam, or projection weld, the depression on the exterior surface or surfaces of the base metal.

|

Induction heating

- Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, through heat generated in the object by eddy currents. See induction heating systems

|

Inert gas

- A gas which does not normally combine chemically with the base metal or filler metal. See also protective atmosphere.

|

Infrared radiation

- Electromagnetic energy with wavelengths from 770 to 12000 nanometers.

|

Intergranular penetration

- The penetration of a filler metal along the grain boundaries of a base metal.

|

Intermittent weld

- A weld in which the continuity is broken by recurring unwelded spaces.

|

Interpass temperature

- In a multiple-pass weld, the temperature (minimum or maximum as specified) of the deposited weld metal before the next pass is started.

|

Inverter

- Power source that increases the frequency of the incoming primary power, thus providing for a smaller size machine and improved electrical characteristics for welding, such as faster response time and more control for pulse welding.

|

Jimmy Jammer

- Semi-Automatic Welding System composed of a manipulator, weld oscillator (oscillating welding torch), cross slide, positioner and turning rolls. The semi-automatic weld oscillator controls the positioners and turning rolls.

|

Joined buildup sequence

- The order in which the weld beads of a multiple-pass weld are deposited with respect to the cross section of the joint.

|

Joint

- The junction of members or the edges of members which are to be joined or have been joined.

|

Joint clearance

- The distance between the faying surfaces of a joint. In brazing this distance is referred to as that which is present either before brazing, at the brazing temperature, or after brazing is completed.

|

Joint design

- The joint geometry together with the required dimensions of the welded joint.

|

Joint efficiency

- The ratio of the strength of a joint to the strength of the base metal (expressed in percent).

|

Joint geometry

- The shape and dimensions of a joint in cross section prior to welding.

|

Joint penetration

- The minimum depth a groove or flange weld extends from its face into a joint, exclusive of reinforcement. Joint penetration may include root penetration.

|

Joint welding procedure

- The materials, detailed methods and practices employed in the welding of a particular joint.

|

Kerf

- The width of the cut produced during a cutting process.

|

Keyhole TIG

- A high speed, full penetration GTAW welding technology that offers enormous productivity, cost and quality advantages over existing processes in stainless steels and other corrosion resistant materials. It requires no edge beveling, uses as little as 10 percent of the gas normally required, and produces highly repeatable, X-ray quality welds with superb cap and root aesthetics.

|

Kilogram (kg)

- The kilogram or kilogramme (SI unit symbol: kg) is the base unit of mass in the International System of Units (SI). 1 Kilogram = 2.2 pounds | 1 pound = 0.453592 Kilograms.

|

KVA (Kilovolt-amperes)

- Kilovolt-amperes. The total volts times amps divided by 1,000, demanded by a welding power source from the primary power furnished by the utility company.

|

KW (Kilowatts)

- Primary KW is the actual power used by the power source when it is producing its rated output. Secondary KW is the actual power output of the welding power source. Kilowatts are found by taking volts times amps divided by 1,000 and taking into account any power factor.

|

Lap joint

- A joint between two overlapping members.

|

Layer

- A stratum of weld metal or surfacing material. The layer may consist of one or more weld beads laid side by side.

|

Leg of a fillet weld

- The distance from the root of the joint to the toe of the fillet weld.

|

Lift-Arc™

- This feature allows TIG arc starting without high frequency. Starts the arc at any amperage without contaminating the weld with tungsten. A Miller Technology Exclusive.

|

Lightly coated electrode

- A filler metal electrode consisting of a metal wire with a light coating applied subsequent to the drawing operation, primarily for stabilizing the arc.

|

Liquidus

- The lowest temperature at which a metal or an alloy is completely liquid.

|

Local preheating

- Preheating a specific portion of a structure.

|

Local stress relief heat treatment

- Stress relief heat treatment of a specific portion of a structure.

|

Longitudinal sequence

- The order in which the increments of a continuous weld are deposited with respect to its length.

|

Low Fume Pulse™

- Technology developed by Lincoln Electric which simplifies the balancing act between weld-fume control and weld floor productivity. This advanced pulsed welding process maximizes arc performance while effectively controlling heat-input.

|

Low OCV Stick™

- Reduces OCV on several Maxstar® and Dynasty® models when power source is not in use, eliminating need for add-on voltage reducers. A Miller Technology Exclusive.

|

LVC™ (Line Voltage Compensation)

- Keeps the output of a power source constant, regardless of minor fluctuations in input power. A Miller Technology Exclusive.

|

LVC™ (Line Voltage Compensation)

- Keeps the output of a power source constant, regardless of minor fluctuations in input power. A Miller Technology Exclusive.

|

Machine welding

- Welding with equipment which performs the welding operation under the constant observation and control of a welding operator. The equipment may or may not perform the loading and unloading of the work.

|

Manual welding

- A welding operation performed and controlled completely by hand.

|

Melt-thru

- Complete joint penetration for a joint welded from one side. Visible root reinforcement is produced.

|

Melting range

- The temperature range between solidus and liquidus.

|

Melting rate

- The weight or length of electrode melted in a unit of time.

|

Metal cored electrode

- Composite filler metal electrode consisting of a metal tube or other hollow configuration containing alloying ingredients. Minor amounts of ingredients providing such functions as arc stabilization and fluxing of oxides may be included. External shielding gas may or may not be used.

|

Metal electrode

- A fillet or non-filler metal electrode, used in arc welding or cutting consisting of a metal wire or rod that has been manufactured by any method and that is either bare or covered with a suitable covering or coating.

|

Metallic bond

- The principal bond which holds metals together and which is formed between base metals and filler metals in all welding processes. This is a primary bond arising from the increased spatial extension of the valence electron wave functions when an aggregate of metal atoms is brought close together.

|

Method

- An orderly arrangement or set form of procedure to be used in the application of welding or allied processes.

|

Microprocessor

- One or more integrated circuits that can be programmed with stored instructions to perform a variety of functions.

|

MIG Welding

- MIG is an acronym for Metal-Inert-Gas, also known as GMAW or Gas Metal Arc Welding. This arc welding process uses a spooled, continuously fed filler metal (consumable) electrode. Shielding is provided by externally supplied gas or gas mixtures. Learn More about: Aluminum MIG Welding, MIG Packages, MIG Wirefeeder Welders

|

MIG/MAG GMAW Welding

- MIG stands for Metal Inert Gas. Only inert gases or gas mixtures are used for the shielding gas when MIG welding. Typical inert gases used for MIG welding are argon and helium. These gases are usually used for MIG welding of aluminium and other non-ferrous metals. MAG stands for Metal Active Gas. Active gas mixtures have been developed primarily for welding steels. Typical shielding gases are mixtures of argon, carbon dioxide and oxygen e.g. CO2 , Ar + 2 to 5% O2 , Ar + 5 to 25% CO2 and Ar + 10% CO2 + 5% O 2 . The composition of the shielding gas has a substantial effect on the stability of the arc, metal transfer and the amount of spatter. The shielding gas also affects the behaviour of the weld pool, particularly its penetration and the mechanical properties of the welded joint. In the US, both MIG and MAG welding are described by the term GMAW (Gas Metal Arc Welding).

|

Missouri Mule (MM) Series

- Turning rolls manufactured by Pandjiris with a capacity range of 30,000 lbs to 180,000 lbs. or more. Designed for heavy-duty use. Often used in combination with a manipulator for applications that require both circumferential and longitudinal automated welding.

|

Molten weld pool

- The liquid state of a weld prior to solidification as weld metal.

|

MTE

- Miller Technology Exclusive

|

MVP™ (Multi-Voltage Plug)

- This Miller Technology Exclusive allows connection of Millermatic® DVI™ or Passport™ to 115- or 230-volt receptacles without tools — just choose the plug that fits the receptacle.

|

Nozzle

- A device which directs shielding media.

|

Open-Circuit Voltage (OCV)

- The difference of electrical potential between two terminals when no current is flowing in the welding circuit. Also known as no-load voltage, arc welding involves open circuit (when not welding) voltages from 20 volts to 100 volts. A welding machine that is turned on but not being used for welding at the moment will have an open-circuit voltage applied to the cables attached to the output terminals of the welding machine.

|

Overlap

- The protrusion of weld metal beyond the toe, face, or root of the weld.

|

Pak

- A rugged tubular steel frame enclosure designed to accommodate multiple power supplies for multi-operator welding systems. Red-D-Arc’s modular Pak frames are available in 4Pak, 6Pak and 8Pak configurations.

|

Palm™ OS Compatibility

- Replaces the need for data cards and remote control pendants on Axcess models.

|

Paralleling

- Running multiple power generators to form a large capacity power source with redundancy. Often used for mission critical operations such as oilfield and emergency backup power. More about paralleling generators.

|

Partial joint penetration

- Joint penetration which is less than complete.

|

Pass

- A single progression of a welding or surfacing operation along a joint, weld deposit, or substrate. The result of a pass is a weld bead, layer, or spray deposit.

|

Peel test

- A destructive method of inspection which mechanically separates a lap joint by peeling.

|

Peening

- The mechanical working of metals using impact blows.

|

Piper Series

- Turning rolls manufactured by Pandjiris with a capacity range of 1,500 lbs. to 10,000 lbs: Mini Pipers, Piper 3, and Super Piper. Designed for smaller capacity applications.

|

Plano lens (eye protection)

- A lens which does not incorporate correction.

|

Plasma

- A gas that has been heated to an at least partially ionized condition, enabling it to conduct an electric current.

|

Plasma arc welding (PAW)

- An arc welding process which produces coalescence of metals by heating them with a constricted arc between an electrode and the workpiece (transferred arc) or the electrode and the constricting nozzle (non transferred arc). Shielding is obtained from the hot, ionized gas issuing from the orifice which may be supplemented by an auxiliary source of shielding gas. Shielding gas may be an inert gas or a mixture of gases. Pressure may or may not be used, and filler metal may or may not be supplied.

|

Plug weld

- A circular weld made through a hole in one member of a lap or T-joint fusing that member to the other. The walls of the hole may or may not be parallel and the hole may be partially or completely filled with weld metal. (A fillet welded hole or a spot weld should not be construed as conforming to this definition.)

|

Polarity

- Electrode welding polarity affects the penetration level of the weld. With most arc welding processes, DC+ (direct current electrode positive) polarity produces more weld penetration, because more arc energy is focused into the base plate. Conversely, DC- (direct current electrode negative) polarity produces less weld penetration, because more arc energy is focused into the electrode and not into the base plate. This is the case with the shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux cored arc welding (FCAW) and SAW processes. The exception is the gas tungsten arc welding (GTAW) process, in which the effect of polarity on penetration is opposite. With GTAW, DC- polarity results in more weld penetration (with DC+ polarity generally not used).

|

Porosity

- Cavity type discontinuities formed by gas entrapment during solidification.

|

Positioned weld

- a weld made in a joint which has been so placed as to facilitate making the weld. See: welding positioners.

|

Postheating

- The application of heat to an assembly after a welding, brazing, soldering, thermal spraying or cutting operation.

|

Postweld heat treatment

- Any heat treatment subsequent to welding.

|

Pounds Per Square Inch (psi)

- A measurement equal to a mass or weight applied to one square inch of surface area.

|

Power Efficiency

- How well an electrical machine uses the incoming electrical power.

|

Power Factor Correction

- Normally used on single-phase, constant current power sources to reduce the amount of primary amperage demanded from the power company while welding.

|

Power Mode®

- Enhanced MIG mode developed by Lincoln Electric which can deliver excellent arc stability with reduced spatter at high travels speeds, resulting from an extended short arc range at higher wire feed speed procedures. It also yields a tight and stable arc in spray transfer.

|

Precision Pulse™

- Enhanced MIG pulse mode by Lincoln Electric featuring a tight, focused arc for fast vertical up welding and outstanding out-of-position puddle control.

|

Preheat temperature

- A specified temperature that the base metal must attain in the welding, brazing soldering, thermal spraying, or cutting area immediately before these operations are performed.

|

Preheating

- The application of heat to the base metal immediately before welding, brazing, soldering, thermal spraying, or cutting. See > Induction Heating Equipment Used for Preheating

|

Primary Power

- Often referred to as the input line voltage and amperage available to the welding machine from the shop's main power line. Often expressed in watts or kilowatts (KW), primary input power is AC and may be single-phase or three-phase.

|

Prime power generator rating

- Prime power ratings can be defined as having an “unlimited run time”, or essentially a generator that will be used as a primary power source and not just for standby or backup power.

|

Procedure

- The detailed elements (with prescribed values or ranges of values) of a process or method used to produce a specific result.

|

Procedure qualification

- The demonstration that welds made by a specific procedure can meet prescribed standards.

|

Progressive block sequence

- A block sequence during which successive blocks are completed progressively along the joint, either from one end to the other or from the center of the joint toward either end.

|

Protective atmosphere

- A gas envelope surrounding the part to be brazed, welded or thermal sprayed, with the gas composition controlled with respect to chemical composition, dew point, pressure, flow rate, etc. Example are inert gases, combusted fuel gases, hydrogen and vacuum.

|

Pulse

- A current of controlled duration through a welding circuit.

|

Pulse time

- The duration of a pulse.

|

Pulse-on-Pulse®

- Arc modulation MIG pulse mode by Lincoln Electric that can deliver a TIG (GTAW)-like bead appearance.

|

Pulsed MIG (MIG-P)

- A modified spray transfer process that produces no spatter, because the wire does not touch the weld puddle. Applications best suited for pulsed MIG are those currently using the short circuit transfer method for welding steel, 14 gauge (1.8 mm) and up. Article: Why Use Pulsed MIG?

|

Pulsed power welding

- Any arc welding method in which the power is cyclically programmed to pulse so that effective but short duration values of a parameter can be utilized. Such short duration values are significantly different from the average value of the parameter. Equivalent terms are pulsed voltage or pulsed current welding: see also pulsed spray welding.

|

Pulsed spray welding

- An arc welding method in which the current in pulsed to utilize the advantages of the spray mode of metal transfer at average currents equal to or less than the globular to spray transition current.

|

Pulsed TIG (TIG-P)

- A modified TIG process appropriate for welding thinner materials.

|

Pulsing

- Sequencing and controlling the amount of current, the frequency and the duration of the welding arc.

|

Push Angle

- The travel angle when the electrode is pointing in the direction of travel. Defines the position of welding guns, welding torches, high energy beams, welding rods, thermal cutting and thermal spraying torches, and thermal spraying guns in a forward direction.

|

Rapid X™

- Premium MIG pulse mode developed by Lincoln Electric, designed to deliver higher travels speeds and extremely low spatter levels.

|

Rapid Z™

- Lincoln Electric process designed to increase stability and travel speeds, while reducing spatter and internal porosity on Zinc coated materials.

|

RapidArc®

- Accelerated MIG pulse mode with a short arc length compared to pulse and CV-spray for high travel speed applications. Developed by Lincoln Electric.

|

Rated Load

- The amperage and voltage the power source is designed to produce for a given specific duty cycle period. For example, 300 amps, 32 load volts, at 60 percent duty cycle.

|

Reaction stress

- The residual stress which could not otherwise exist if the members or parts being welded were isolated as free bodies without connection to other parts of the structure.

|

Reactor (arc welding)

- A device used in arc welding circuits for the purpose of minimizing irregularities in the flow of welding current.

|

Regulated Metal Deposition (RMD)

- An advanced welding process developed by Miller Electric. Also known as modified short-circuit MIG, it is a precisely controlled short-circuit transfer technology that improves welding quality and productivity on stainless steel pipe. See the Miller Pipeworx 400.

|

Reinforcement of weld

- Weld metal in excess of the quantity required to fill a joint.

|

Residual stress

- Stress remaining in a structure or member as a result of thermal or mechanical treatment or both. Stress arises in fusion welding primarily because the melted material contracts on cooling from the solidus to room temperature.

|

Resistance Spot Welding (RSW)

- A process in which two pieces of metal are joined by passing current between electrodes positioned on opposite sides of the pieces to be welded. There is no arc with this process. For more information on Resistance Spot Welding, please see Resistance Spot Welding Tech Tips.

|

Reverse polarity

- The arrangement of direct current arc welding leads with the work as the negative pole and the electrode as the positive pole of the welding arc. A synonym for direct current electrode positive.

|

RMS (Root Mean Square)

- The "effective" values of measured AC voltage or amperage. RMS equals 0.707 times the maximum or peak value.

|

Root crack

- A crack in the weld or heat-affected zone occurring at the root of a weld.

|

Root face

- That portion of the groove face adjacent to the root of the joint.

|

Root of joint

- That portion of a joint to be welded where the members approach closest to each other. In cross section the root of the joint may be either a point, a line or an area.

|

Root of weld

- The points, as shown in cross section, at which the back of the weld intersects the base metal surfaces.

|

Root opening

- The separation between the members to be joined at the root of the joint.

|

Root penetration

- The depth that a weld extends into the root of a joint measured on the centerline of the root cross section.

|

Root reinforcement

- Reinforcement of weld at the side other than that from which welding was done.

|

Root surface

- The exposed surface of a weld on the side other than that from which welding was done.

|

Scarf joint

- A form of butt joint.

|

Scratch Start TIG

- A common method of striking an arc in the TIG welding process which involves dragging the tungsten electrode across the surface of the metal. Not the cleanest method of starting a TIG weld. Stick welders can be converted to use for scratch TIG with the addition of an air cooled TIG torch and argon gas.

|

Seal weld

- Any weld designed primarily to provide a specific degree of tightness against leakage.

|

Seam weld

- A continuous weld made between or upon overlapping members, in which coalescence may start and occur on the faying surfaces, or may have proceeded from the surface of one member. The continuous weld may consist of a single weld bead or a series of overlapping spot welds. See seam welders

|

Seam welding

- The making of seam welds

|

Secondary circuit

- That portion of a welding machine which conducts the secondary current between the secondary terminals of the welding transformer and the electrodes, or electrode and work.

|

Selective block sequence

- A block sequence in which successive blocks are completed in a certain order selected to create a predetermined stress pattern.

|

Semi-automatic arc welding

- Arc welding with equipment which controls only the filler metal feed. The advance of the welding is manually controlled.

|

Semi-blind joint

- A joint in which one extremity of the joint is not visible.

|

Series submerged arc welding (SAW-S)

- A submerged arc welding process variation in which electric current is established between two (consumable) electrodes which meet just above the surface of the work. The work is not in the electrical circuit.

|

SharpArc®

- Optimizes the size and shape of the arc cone, bead width and appearance, and puddle fluidity. Available on the Millermatic® 350/350P. A Miller Technology Exclusive.

|

Shielded carbon arc welding (SCAW)

- A carbon arc welding process variation which produces coalescence of metals by heating them with an electric arc between a carbon electrode and the work. Shielding is obtained from the combustion of a solid material fed into the arc or from a blanket of flux on the work or both. Pressure may or may not be used and filler metal may or may not be used.

|

Shielded metal arc welding (SMAW)

- An arc welding process which produces coalescence of metals by heating them with an arc between a covered metal electrode and the work. Shielding is obtained from decomposition of the electrode covering. Pressure is not used and filler metal is obtained from the electrode. SMAW is also referred to as MMA, MMAW (Manual Metal Arc Welding) and commonly as Stick Welding. Learn more about Stick Welding Applications.

|

Shielding gas

- Protective gas used to prevent atmospheric contamination.

|

Short circuiting transfer (gas metal arc welding)

- A type of metal transfer in which melted material from a consumable electrode is deposited during repeated short circuits.

|

Shrinkage void

- A cavity-type discontinuity normally formed by shrinkage during solidification.

|

Sieve analysis

- A method of determining particle size distribution, usually expressed as the weight percentage retained upon each of a series of standard screens of decreasing mesh size.

|

Single-Phase Circuit

- An electrical circuit producing only one alternating cycle within a 360-degree time span.

|

Single-welded joint

- In arc and gas welding, any joint welded from one side only.

|

Skull

- The unmelted residue from a liquated filler metal.

|

Slag inclusion

- Nonmetallic solid material entrapped in weld metal or between weld metal and base metal.

|

Slot weld

- A weld made in an elongated hole in one member of a lap or T-joint joining that member to that portion of the surface of the other member which is exposed through the hole. the hole may be open at one end and may be partially or completely filled with weld metal. (A fillet welded slot should not be construed as conforming to this definition).

|

Slugging

- The act of adding a separate piece or pieces of material in a joint before or during welding that results in a welded joint not complying with design, drawing, or specification requirements.

|

Smart Fuel Tank

- Tank's design minimizes chance of fuel backflow.

|

Solidus

- The highest temperature at which a metal or alloy is completely solid.

|

Spacer strip

- A metal strip or bar prepared for a groove weld, and inserted in the root of a joint to serve as a backing and to maintain root opening during welding. It can also bridge an exceptionally wide gap due to poor fitup.

|

Spatter

- In arc and gas welding, the metal particles expelled during welding and which do not form a part of the weld.

|

Spatter loss

- Metal lost due to spatter.

|

Spool

- A type of filler metal package consisting of a continuous length of electrode wound on a cylinder (called the barrel) which is flanged at both ends. The flange extends below the inside diameter of the barrel and contains a spindle hole.

|

Spool Gun

- Spool guns, consisting of a gun with a pistol grip and a 4-inch diameter wire spool mounted on the back end, provide mobility. Though most commonly used for welding aluminum because they solve the feeding problems encountered by push-only systems, some contractors and fabricators also use them for running a second type of wire (e.g., stainless steel or a smaller diameter solid wire). With 15- or 30-foot cable options, spool guns also provide mobility when working around large weldments. There are two classes of spool guns, ones that work with both CC or CV power sources and those that work with only CV power sources.

|

Spot weld

- A weld made between or upon overlapping members in which coalescence may start and occur on the faying surfaces or may proceed from the surface of one member. The weld cross section (plan view) is approximately circular.

|

Spot welding

- The making of spot welds.

|

Spray transfer (arc welding)

- A type of metal transfer in which molten filler metal is propelled axially across the arc in small droplets.

|

Square-groove weld

- A type of groove weld.

|

Squarewave™

- The AC output of a power source that has the ability to rapidly switch between the positive and negative half cycles of alternating current.

|

Staggered intermittent fillet welding

- Two lines of intermittent fillet welding on a joint in which the fillet weld increments is one line are staggered with respect to those in the other line.

|

Standby power generator rating

- Standby power generators are most often used in emergency situations, such as during a power outage. It is ideal for applications that have another reliable continuous power source like utility power.

|

Stick Welding SMAW (Shielded Metal Arc Welding)

- In this welding process, an electric arc is created between a coated consumable electrode and the work piece to be welded, causing the parent material to be fused together and the electrode to melt. The electrode is of a similar material to the parent material and by melting both together it provides the weld (or joint) with a reinforcing filler material. The electrode has a flux coating of either a basic, rutile or cellulose type, as the coating burns it protects the arc and weld pool from the surrounding atmosphere with a gaseous shroud. The slag which solidifies over the newly deposited weld also protects it from the atmosphere while cooling. Stick welding equipment

|

Stitch welding

- The use of intermittent welds to join two or more parts.

|

Straight polarity

- The arrangement of direct current arc welding leads in which the work is the positive pole and the electrode is the negative pole of the welding arc. A synonym for direct current electrode negative.

|

Stranded electrode

- composite filler metal electrode consisting of stranded wires which may mechanically enclose materials to improve properties, stabilize the arc or provide shielding.

|

Stress corrosion cracking

- Failure of metals by cracking under combined action of corrosion and stress, residual or applied. In brazing, the term applies to the cracking of stressed base metal due to the presence of a liquid filler metal.

|

Stress relief cracking

- Intergranular cracking in the heat-affected zone of weld metal that occurs during the exposure of weldments to elevated temperatures during postweld heat treatment or high temperature service.

|

Stress relief heat treatment

- Uniform heating of a structure or a portion thereof to a sufficient temperature to relieve the major portion of the residual stresses, followed by uniform cooling.

|

Stringer bead

- A type of weld bead made without appreciable weaving motion.

|

Stud Welding

- A process for attaching a fastener, bolt or nut to a metal base. Fasteners attached during the stud welding process are usually threaded, unthreaded or tapped variety. Learn more about the uses of Stud Welding Machines.

|

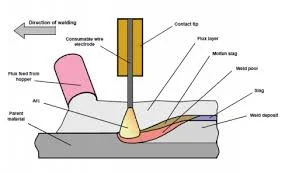

Submerged Arc (SAW)

- A welding process that uses the heat produced by an electric arc between a bare metal electrode and the work. Shielding is supplied by a layer of granular, fusible flux material blanketing the arc.

|

Submerged arc welding (SAW)

- An arc welding process which produces coalescence of metals by heating them with an arc or arcs between a bare metal electrode or electrodes and the work. The arc is shielded by a blanket of granular, fusible material on the work. Pressure is not used and filler metal is obtained from the electrode and sometimes from a supplementary welding rod. View Submerged Arc Welding

|

Substrate

- Any base material to which a thermal sprayed coating or surfacing weld is applied.

|

Sun Vision™

- This Miller Technology Exclusive allows easy reading of digital meters in direct sunlight or shade on Trailblazer® 275 DC and 302.

|

SureStart™

- Provides consistent Axcess® arc starts by precisely controlling power levels for specific wire and gas combinations. A Miller Technology Exclusive.

|

Surface preparation

- The operations necessary to produce a desired or specified surface condition.

|

Surface Tension Transfer (STT)

- An advanced waveform MIG welding process developed by Lincoln Electric. STT uses high frequency inverter technology with advanced waveform control to produce a high-quality weld with less spatter and smoke. Easy to operate and can achieve good weld penetration with low heat input.

|

Surfacing

- The deposition of filler metal (material) on a base metal (substrate) to obtain desired properties or dimensions.

|

Surfacing weld

- A type of weld composed of one or more stringer or weave beads deposited on an unbroken surface to obtain desired properties or dimensions.

|

Synchronized Tandem MIG®

- Lincoln Electric technology which overcomes deposition rate limitations of a single wire by using two wires and specific waveforms. The result is nearly double deposition rates and faster travel speeds.

|

Syncro Start™

- This Miller Technology Exclusive allows selectable customized arc starts on Syncrowave® 200, 250 DX and 350 LX.

|

T-joint

- A joint between two members located approximately at right angles to each other in the form of a T.

|

Tack weld

- A weld made to hold parts of a weldment in proper alignment until the final welds are made.

|

Tanker Series

- Turning rolls manufactured by Pandjiris with a capacity range of 8,000 to 15,000 lbs.: Tanker 80/40 and Tanker 150/75. Designed to handle a wide range of diameter sizes. No wheel adjustments for different diameters.

|

Taps

- Connections to a transformer winding which are used to vary the transformer turns ratio, thereby controlling welding voltage and current.

|

Temporary weld

- A weld made to attach a piece or pieces to a weldment for temporary use in handling, shipping, or working on the weldment.

|

Theoretical throat

- The distance from the beginning of the root of the joint perpendicular to the hypotenuse of the largest right triangle that can be inscribed within the fillet weld cross section.

|

Thermal stresses

- Stresses in metal resulting from non-uniform temperature distribution.

|

Three-Phase Circuit

- An electrical circuit delivering three cycles within a 360-degree time span, and the cycles are 120 electrical degrees apart.

|

TIG Welding

- Also known as GTAW (gas tungsten arc welding) this welding process welds using the heat of a non-consumable tungsten electrode. Filler metal can be used and argon inert gas or inert gas mixtures are used for shielding. Learn more about TIG Welding Applications

|

Tip Saver Short Circuit Protection™

- Shuts down output when the MIG contact tip is shorted to the work, on the Millermatic® 135 and 175. Extends contact tip life and protects machine. A Miller Technology Exclusive.

|

Toe crack

- A crack in the base metal occurring at the toe of a weld.

|

Toe of weld

- The junction between the face of a weld and the base metal.

|

Ton

- A ton is a unit of weight that is equal to 2000 pounds in the United States (short ton) and 2240 pounds in Britain (long ton or imperial ton or displacement ton).

|

Tonne

- A tonne is called a metric ton in the United States to help differentiate between metric and imperial. 1 tonne = 1,000 kilograms = 2,200 pounds

|

Torch

- A device used in the TIG (GTAW) process to control the position of the electrode, to transfer current to the arc and to direct the flow of the shielding gas.

|

Torch Detection™

- Syncrowave® 250 DX and 350 LX detect if TIG torch is water- or air-cooled. A Miller Technology Exclusive.

|

Torch standoff distance

- The distance between a nozzle and a workpiece.

|

Touch Start

- A procedure to initiate an arc for TIG (GTAW). The tungsten is touched against the work piece and then lifted, establishing an arc.

|

Travel angle (electrode)

- The angle that the electrode makes with a reference line perpendicular to the axis of the weld in the plane of the weld axis.

|

Travel angle (pipe)

- The angle that the electrode makes with a reference line extending from the center of the pipe through the puddle in the plane of the weld axis.

|

Travel Angle of Welding Electrode

- The degree of the travel angle, whether a push or drag travel angle, affects how much of the arc force is directed down into the base plate. A travel angle of 0° to 10° (e.g.the electrode perpendicular or almost perpendicular to the plate) will result in more weld penetration. As the travel angle is increased, the level of weld penetration decreases.

|

Tri-Cor™ Technology

- Stabilizer design on the Bobcat™ 250 that delivers smoother welds and decreased spatter with E7018 electrodes, without sacrificing performance with E6010 electrodes. A Miller Technology Exclusive.

|

Trigger Reset

- Permits quick reset at gun rather than at machine.

|

Tungsten

- Rare metallic element with extremely high melting point (3410° Celsius). Used in manufacturing TIG electrodes.

|

Tungsten electrode

- A non-filler metal electrode used in arc welding or cutting, made principally of tungsten.

|

Underbead crack

- A crack in the heat-affected zone generally not extending to the surface of the base metal.

|

Undercut

- A groove melted into the base metal adjacent to the toe or root of a weld and left unfilled by weld metal.

|

Underfill

- A depression on the face of the weld or root surface extending below the surface of the adjacent base metal.

|

Upslope time

- The time during which the welding current continuously increases from the beginning of welding current.

|

Vertical position

- The position of welding in which the axis of the weld is approximately vertical.

|

Vertical position (pipe welding)

- The position of a pipe joint in which welding is performed in the horizontal position and the pipe may or may not be rotated.

|

Volt-Amp Curve

- Graph that shows the output characteristics of a welding power source. Shows voltage and amperage capabilities of a specific machine.

|

Voltage

- The potential difference in charge between two points that acts as a force pushing electrons through a conductor. Sometimes termed electromotive force (EMF).

|

Voltage regulator

- An automatic electrical control device for maintaining a constant voltage supply to the primary of a welding transformer.

|

Voltage sensing wire feeders